Introduction

In the realm of aluminum manufacturing, the titanium gold plating process stands out as a significant advancement in coating technology. Building on the foundation of traditional titanium plating, this method adds crucial steps to enhance the final product’s quality and appearance.

The Titanium Gold Plating Process

The process involves immersing activated aluminum profiles in a solution of salts and hydrochloric acid for chemical treatment, followed by an electroplating stage. The electroplating solution comprises ingredients like nickel sulfate and boric acid, crucial for achieving the desired finish.

Advantages of Titanium Gold Plating

This method is celebrated for its simplicity and effectiveness. A standout feature is the film hardness it imparts to the aluminum profiles (HV ≈ 1500), making them significantly more wear-resistant than traditional 22K gold plating.

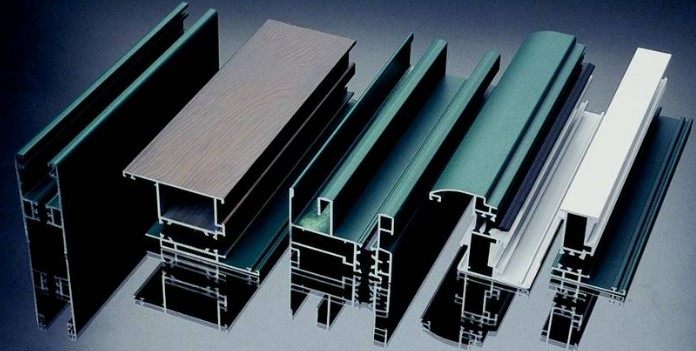

Applications and Varieties

Titanium gold plating enables the production of aluminum profiles in a range of colors and finishes, suitable for various applications across different sectors.

Quality Concerns in Aluminum Profile Production

However, the production of aluminum profiles is not without challenges. Issues like bubbles and inclusions can arise during extrusion, while inadequate oxide film thickness can lead to rust and corrosion.

Chemical Composition and Wall Thickness Standards

Adhering to national standards in chemical composition and wall thickness is paramount. Deviations, often seen in the use of mixed or scrap aluminum, can compromise the safety and integrity of construction projects.

Impact of Inferior Aluminum Profiles

The use of inferior materials and cost-cutting measures can drastically reduce the corrosion resistance and overall quality of the profiles, posing safety risks.

Conclusion

The titanium gold plating process marks a significant advancement in aluminum profile manufacturing, offering enhanced durability and aesthetic appeal. However, the importance of adhering to high-quality standards in production cannot be overstated, balancing innovation with safety and reliability.